Power

You Can

Depend On

A complete line of safe, reliable power and conversion systems

Technology

Driving energy storage innovation for over 100 years, manufacturing and supporting systems for the conversion and storage of electrical power.

Our Driving Force

As a global leader in energy storage solutions and services for the uninterruptible power supply, telecommunications, energy and infrastructure, and renewable energy markets, C&D is committed to providing high quality, safe, reliable, cost-effective power storage products and services to our customers.

Industries

Introducing a High Temperature Telecom Battery for Lower TCO

Introducing TEL-HT telecom high temperature valve regulated lead–acid (VRLA) batteries. The TEL-HT series features C&D’s longest-lasting VRLA batteries for the telecom market and creates approximately 20% cost savings to provide operators with reliable, cost-efficient backup power.

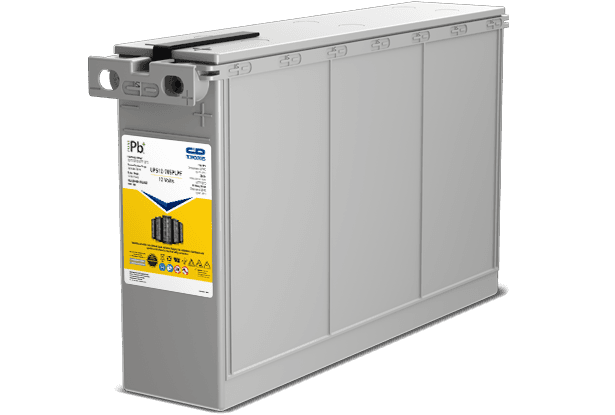

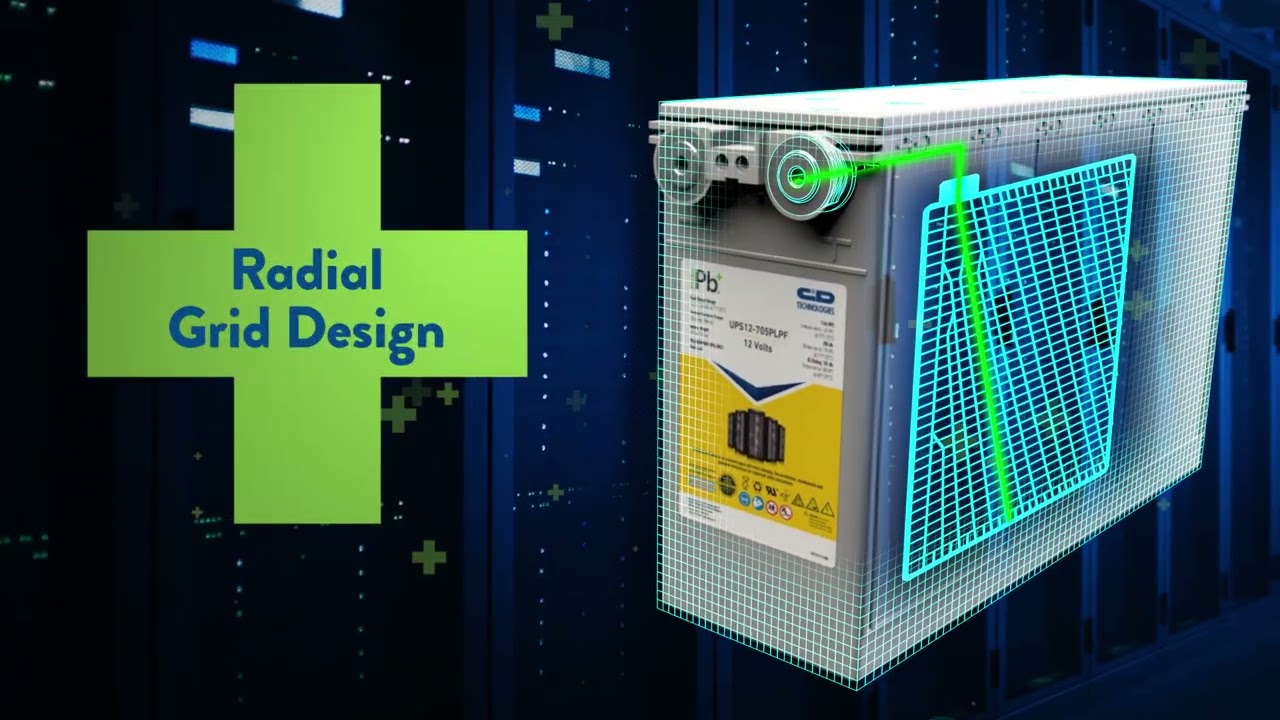

Get the Power of the Plus

From the inside out, Pure Lead Plus batteries are designed to give you long-lasting performance.

Pure Lead Plus is simply a superior battery for data center UPS systems.”

Steve Micallef, Client Success ManagerOur commitment to sustainability

Our team of experts are committed to design and manufacture our products in the most sustainable way and support our customers with environmentally conscious disposal.

Latest from C&D Technologies

Explore the C&D Solution Portal

C&D's Solution Portal is a secure website for customers to size and spec C&D stationary battery products from their desktop or smartphone.

Register for access to resources like our Battery Sizing Tool, Ratings Tables, Key Calculations, Rack Tools, and other resources, including accessories info, system and cell drawings, technical documents, and much more.

Get the latest C&D updates delivered to your inbox

Join our mailing list to stay up to date with C&D Technologies.